Our Services

We help you in achieving a precise and lovable prototype of your preferences. With our hard-working and determined team, we are always beside you to help you achieve your project with high quality and in less time.

Rapid prototyping

Create a model or a physical part using 3D AutoCAD (Automatic Computer Aided Designing) and additive manufacturing.

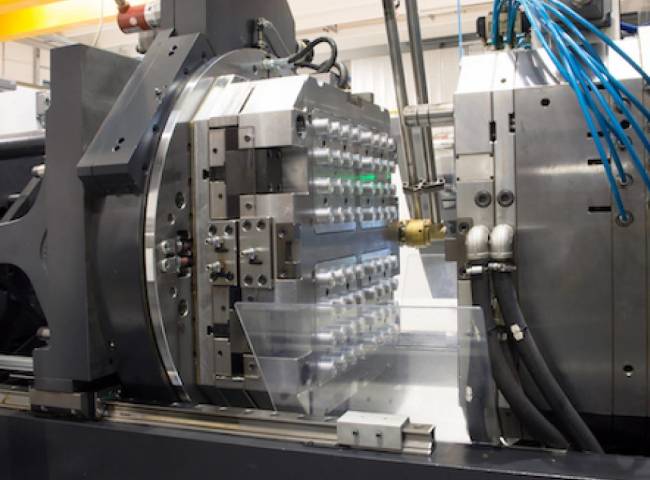

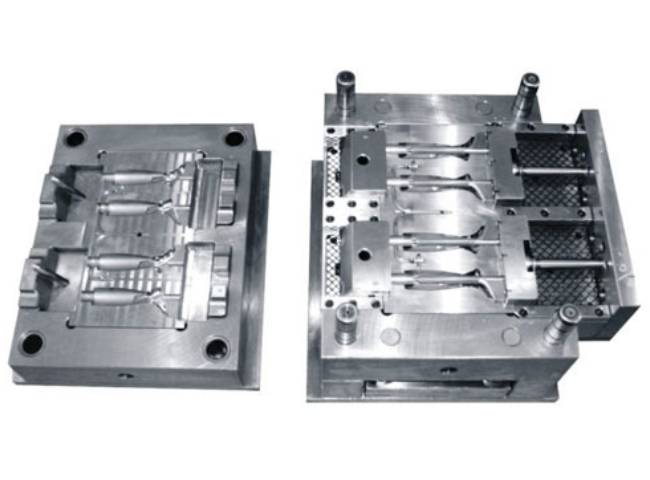

Injection molding

Obtain plastic molded products by injecting molten plastic materials into a closed mold tool, allowing it to cool down and heat..

Vacuum casting

A casting process is used to create elastomer prototypes. The liquid material is drawn into the mold using a vacuum.

Die casting

Produce the most dimensionally stable and durable metal parts, using the principle of forcing molten metal into a mold cavity using high pressure.

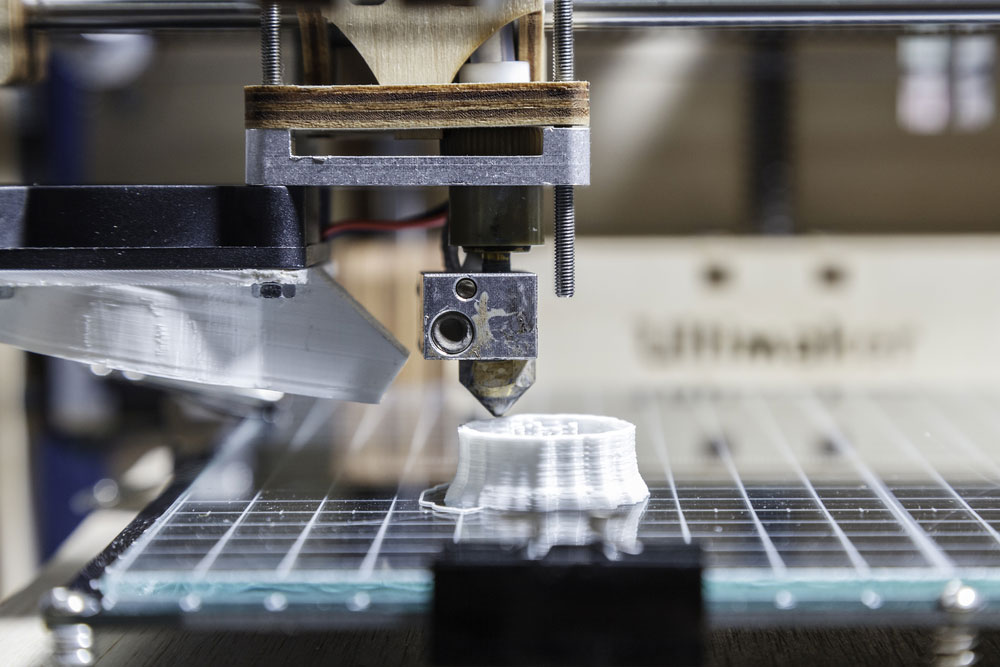

3D Printing

Design a customized model, transform it into a 3D model of any type of material of your choice quickly.

Rapid tooling

Test your products with actual materials, decreasing the time taken and production costs before the mass production.

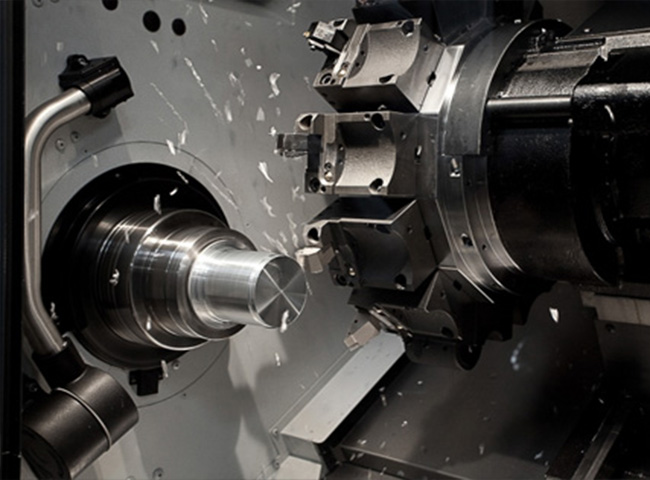

CNC machining

With different techniques, various cutting types, a CNC machine makes your product fulfilling with high accuracy.

Finishing Services

Get your finished and perfect product with excellent finishing service, including binding, painting, cutting, laminating, and many more.

Our Strengths

Our team is a determined and highly talented group of engineers. Their experience and knowledge will lead to producing an accurate model or tool you want. We make sure that you are satisfied with your project in terms of accuracy and timing. We assume that the quality of our team will be directly proportional to the one of the product.

Our team has members whose knowledge is complementary to each other. Their experience in various fields like businesses, mathematics, computers will help us create sophisticated products.

Learn and Grow

We know that learning and adapting to the latest technology will help us be a better team and work towards better manufacturing of products and a better experience for you. We are all about excellence in every angle and put the right team members who suit your project.

We also look forward to learning and gaining knowledge in other fields, which would help us improve and work efficiently. We help you get your product done and give you an adequate understanding of the work and its dimensions.

Something better

We are a straightforward and goal-oriented company. Our intentions are sincere and easy. We strongly believe in our customer satisfaction. We always check on ourselves periodically, ensuring that we have become better and are working more professionally. We have always crosschecked our peers on our timing and quality.

We also make sure that we use the right machinery with sharp tools, which decrease the production time and costs. The measurement of our success is by the happiness and fulfillment of the customer with the final product.

Answers to Your Questions

Which kind of raw materials do you use?

We used materials according to the guidance of the customer. We provide a wide range of raw product materials. Whatever the product is, we make sure that we get the best quality products.

What is the long-term vision for your business?

Our goal is to increase our production level and work for customers across the country while maintaining our quality.

What is the process to order my product?

All you need to do is contact us through mobile or email and give every detail about the product from the raw material to model and dimensions. You can also visit our office during our working hours.

Is your website up to date?

Yes, we are updating our website from time to time. We need to work more on ourselves in this aspect.

How long do you take to finish a product?

The timeline of any product is extensively dependent on the type and complexity of the product. On average, a product takes around 3-8 weeks.