Injection Molding

Injection molding

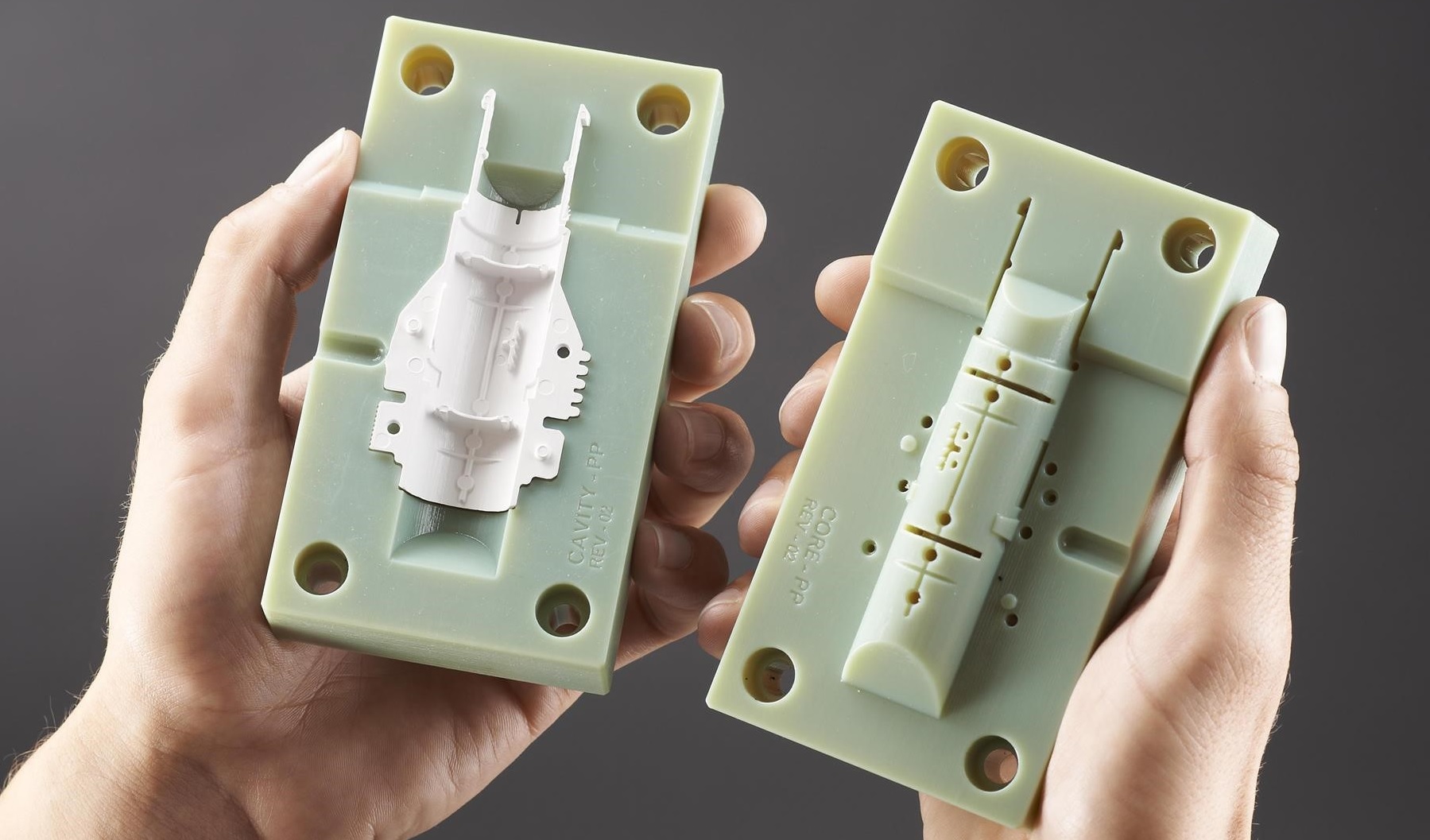

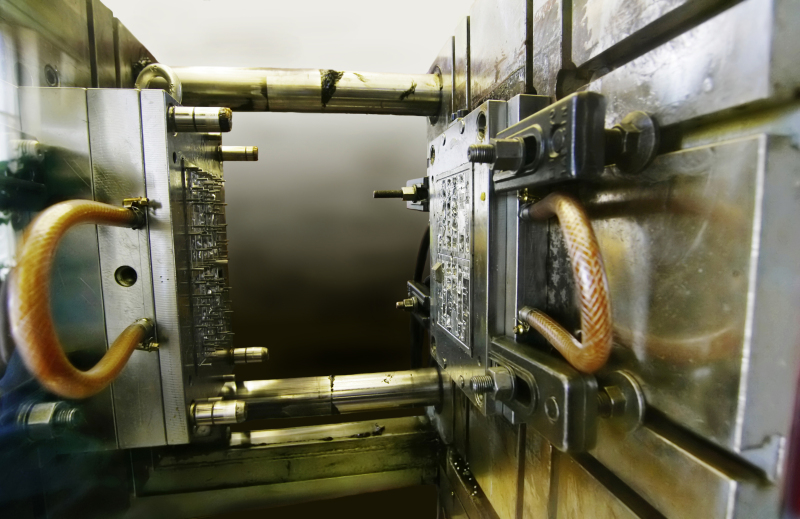

Injection molding is used to make molded plastic products. The molten plastic is injected inside a closed mold, and it is allowed to cool down. The production charges of injection molding are low. Our team of highly experienced engineers works in cutting the time of production. With our highly advanced rapid tooling, we cut losses of time and money.

Economical

We produce the tools and prototypes in bulks, cutting the charges. The process is repeatable, and is easy to create the prototypes as the machinery used to create the prototypes are similar. Injection molding includes low-risk techniques, giving the best products at cheap and affordable rates.

Risk reduction

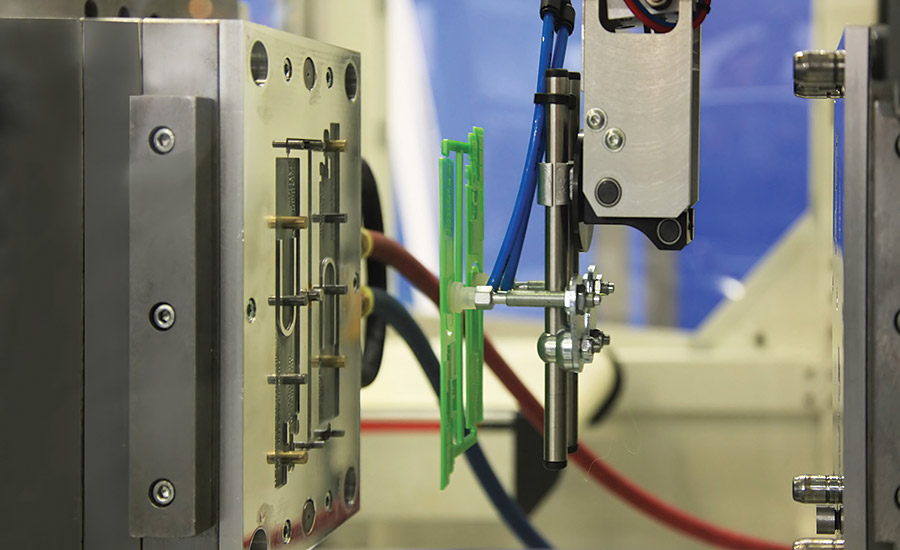

Choosing techniques like AutoCAD and CNC machining can reduce the risks in the final stage of manufacturing. Injection molding is also one of the fastest methods to make tools and parts. We also minimize time using faster machines. Injection molding is hence fast, effective, and cheap.

Produce small tools and parts

We trained our team in producing prototypes in efficient ways. We will make sure of creating small parts with our knowledge and advanced machinery in all available technologies. We manufacture the tools on a large scale and this helps us reduce the costs. Our team always works to satisfy our customers with our work.