Vacuum Casting

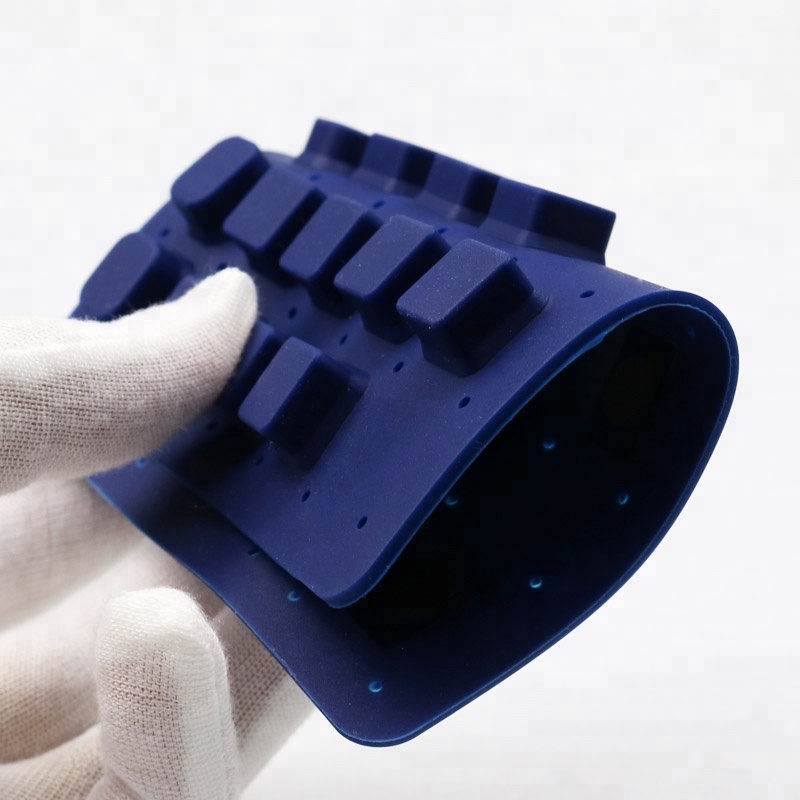

We use the casting process to create elastomer prototypes. The liquid material is drawn into the mold using a vacuum. We produce the engineering products in highly detailed models using vacuum casting. Our customer looks forward to optimizing their businesses to a whole next level. We hence help them achieve their goals by providing the products they need.

Fast and effective

We can duplicate loads of plastic parts using vacuum casting. We mostly use materials like resins and elastomers in building the products. But, if our client wants us to produce their tools with other materials, we also use gold, bronze, marble, aluminum. Manufacturing the parts in large quantities helps us create the prototypes faster.

Better finishing

Vacuum casting is the best method to produce prototypes with a better finishing and classier product. In the process of vacuum casting, the vacuum pulls the liquid material into the mold, unlike injection molding. That removes the air bubbles and gives the product a finer detail and undercuts.

Applications

Tools produced through vacuum casting have a wide range of usage in daily lives. The prototypes are applicable in market research, visual prototype, consumer goods, investor pitches, testing, medical devices, etc. Construction of different types of wall plaques and showpieces is done using vacuum casting.